Inspection Report

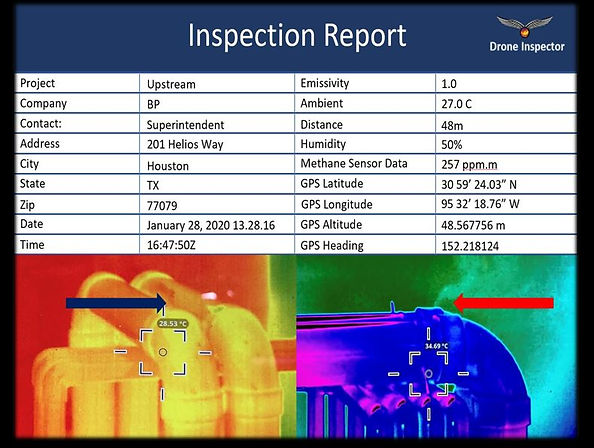

After a survey, our Safety & Reliability Engineering Team generates an Inspection Report to characterize leaks and their origins.

This visual and measurement data is processed and analyzed by our Engineering Team to generate reports for leak analysis. These services allow our clients to see otherwise invisible fugitive emissions in the most efficient and cost-effective manner possible.

We build a database of documented leaks that becomes a historical record of the leak progression or stability. This data, information, and historical record become the bases of remedial actions and process evaluations derived from further analysis by our Engineering Team.

We deliver a catalog of information about each leak, including its location, gas components, visuals, and the environmental conditions during the inspection including:

-

mass of a contaminant per million units of total mass (ppm.m)

-

concentrations of a leaked contaminants

-

thermal images of leaks

-

videos of leaks with corresponding temperature data

-

survey lines

-

3D profiles

-

tables

-

emissivity

-

distance

-

relative humidity

-

color coded profiles